The Function of a Galvanometer Scanner in Enhancing Laser Interaction Equipments

The Function of a Galvanometer Scanner in Enhancing Laser Interaction Equipments

Blog Article

How a Galvanometer Scanner Improves Efficiency in Laser Scanning Technologies

The assimilation of galvanometer scanners in laser scanning modern technologies represents a critical innovation in precision engineering. By facilitating rapid and accurate changes of laser beam instructions, these tools dramatically enhance operational performance across numerous applications, from clinical imaging to commercial inscription.

Understanding Galvanometer Scanners

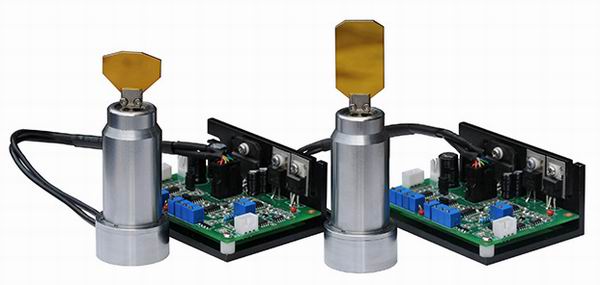

A galvanometer scanner is an innovative gadget that leverages electro-magnetic concepts to achieve accurate angular movement of mirrors or various other reflective surfaces. These scanners run through the interaction of an electrical current and a magnetic area, enabling exact and quick positioning. This innovation is necessary in applications needing high-speed scanning, such as laser engraving, optical communication, and clinical imaging.

Galvanometer scanners are usually characterized by their rapid reaction times and high angular resolution, making them ideal for applications that require rapid activities and exact positioning. Their dependability and efficiency make them an essential element in modern laser scanning innovations, adding considerably to developments in various areas, consisting of production, medical care, and telecoms.

System of Laser Beam Control

The control device relies upon closed-loop feedback systems that continually keep an eye on the light beam's placement. The signals from optical sensing units give real-time data to the control system, enabling rapid modifications to keep precision. This is critical in applications where even small inconsistencies can compromise the quality of the scan or etching.

Additionally, the galvanometer's reaction time is extremely important; high-speed motors make it possible for quick motions, guaranteeing that the laser light beam can rapidly map complex patterns or do elaborate operations. The integration of electronic signal processing even more boosts the responsiveness and accuracy of the galvanometer scanner. Generally, the mechanism of laser beam of light control through galvanometer scanners exhibits the blend of sophisticated design and innovation, generating high-performance results in laser scanning applications.

Benefits of Boosted Precision

Boosted precision in laser scanning modern technologies uses significant benefits throughout numerous applications, from commercial production to clinical procedures. The combination of galvanometer scanners enables highly precise beam positioning, which is essential for tasks needing careful information. This enhanced accuracy makes certain that the laser can target particular locations with marginal inconsistency, leading to remarkable top quality results.

In industrial contexts, specific laser scanning leads to boosted product uniformity and lowered product waste. In medical applications, the accuracy of laser procedures can substantially affect individual end results.

Moreover, improved precision facilitates innovative applications such as 3D imaging and microfabrication, where even minute inaccuracies can result in significant mistakes. By supplying repeatable and reputable laser positioning, galvanometer scanners contribute to the total performance and effectiveness of laser systems. In recap, the benefits of enhanced accuracy not only boost functional efficiency yet also boost the standards of top quality and security in various sectors.

Applications in Various Industries

The convenience of galvanometer scanners in laser scanning technologies prolongs across multiple markets, each taking advantage of the accuracy they supply. In the medical area, these scanners are critical in applications such as laser surgical treatment and imaging, permitting extremely precise targeting of tissues while lessening damages to surrounding areas - galvanometer scanner. Their fast feedback and fine resolution are critical in generating top quality results

In the manufacturing market, galvanometer scanners boost procedures like laser inscription and cutting. Their capacity to quickly route laser beam of lights onto surfaces makes it possible for reliable manufacturing lines, improving speed and accuracy in developing complex layouts or components.

The vehicle industry likewise takes advantage of galvanometer innovation for quality assurance and examinations (galvanometer scanner). By using high-speed scanning, makers can find issues in assemblies or products, ensuring that items meet rigorous criteria

Moreover, in the entertainment field, galvanometer scanners are used in laser light programs and displays, using dynamic visual experiences with accurate control over laser motions.

Future Patterns in Laser Scanning

Emerging innovations are poised to reinvent the landscape of laser scanning, with galvanometer scanners at the forefront of this improvement. As markets increasingly require accuracy and efficiency, the evolution of galvanometer technology will certainly drive substantial developments in informative post laser scanning applications.

Future fads suggest a growing assimilation of man-made knowledge and device knowing algorithms, which will boost data processing capacities and automate decision-making in real-time. This synergy will certainly allow for more advanced analysis of checked data, bring about boosted accuracy in applications such as 3D modeling and independent navigation.

Moreover, the miniaturization of parts and the growth of innovative products will contribute to lighter, more portable laser scanning systems. This transportability will broaden the reach of laser scanning innovations into formerly unattainable atmospheres, such Going Here as remote terrain and detailed architectural rooms.

The rise of increased reality (AR) and digital truth (VR) applications will likewise form the future of laser scanning. By combining galvanometer scanners with AR and virtual reality, customers will take advantage of immersive experiences that improve visualization and job planning.

Final Thought

To conclude, galvanometer scanners play a crucial function in optimizing laser scanning innovations via their precise control of beam instructions and quick angular adjustments. The assimilation of sophisticated feedback systems and optical sensing units substantially improves operational speed and precision, bring about boosted results in applications such as laser inscription and medical imaging. As industries increasingly adopt these technologies, the ongoing developments in galvanometer scanner layouts are anticipated to additional raise efficiency requirements and widen application possibilities.

The integration of galvanometer scanners in laser scanning innovations represents an essential advancement in precision engineering. Overall, the device of laser beam of light control via galvanometer scanners exhibits the combination of advanced engineering Click Here and technology, producing high-performance end results in laser scanning applications.

By providing repeatable and trustworthy laser positioning, galvanometer scanners add to the overall effectiveness and effectiveness of laser systems.The flexibility of galvanometer scanners in laser scanning modern technologies extends throughout multiple sectors, each benefiting from the precision they give.In verdict, galvanometer scanners play a critical duty in enhancing laser scanning modern technologies with their precise control of light beam direction and fast angular modifications.

Report this page